Enjoy a reduced CO2 footprint without sacrificing the high thermal performance of EPS

Manufactured with raw material made from up to 100% renewable feedstock, saving fossil resources

Independent third-party REDcert2 Certification with full authorisation to manufacture and sell to EU markets

Offers the same benefits of original EPS you’ve come to know: water & moisture resistance, high thermal performance, resistance to ageing and decay, versatile and easy to work with

-

Reduce Your Carbon Footprint

KORE’s Low Carbon EPS insulation offers reduced CO2 emissions of up to 90% during the manufacturing of raw material, helping you achieve BREEAM, LEED & HPI certification with ease

-

Independently Verified

Certified by German technical inspection authority REDcert2. KORE Low Carbon is supplied with a certificate detailing

fossil resource savings and a declaration of saved greenhouse gas emissions -

Manufactured from Renewable Sources

Fossil fuels are replaced with up to 100% renewable feedstock, saving valuable resources while reducing CO2 emissions and creating products that can be fully recycled

-

Available in Range of Insulation Applications

KORE’s Low Carbon EPS Insulation is available for most applications including KORE Fill Diamond, KORE Floor, KORE Insulated Foundation System, KORE External, KORE Roof Insulation and KORE Void Formers & Fillers with more to come!

TECHNICAL INFORMATION

Download the KORE Low Carbon Insulation Product Leaflet >>

Download the BASF Biomass Balance Leaflet >>

Watch the BASF Biomass Balance Approach Video >>

Fully certified

- Manufactured to IS EN 13163:2012+A2:2016 and in an ISO 9001:2015 QMS certified facility

- Full Declaration of Performance Certificates available

- Third-party Environmental Product Declaration certified by IGBC and EPD Ireland

- REDcert2 Certified to offer low carbon EPS to the European market

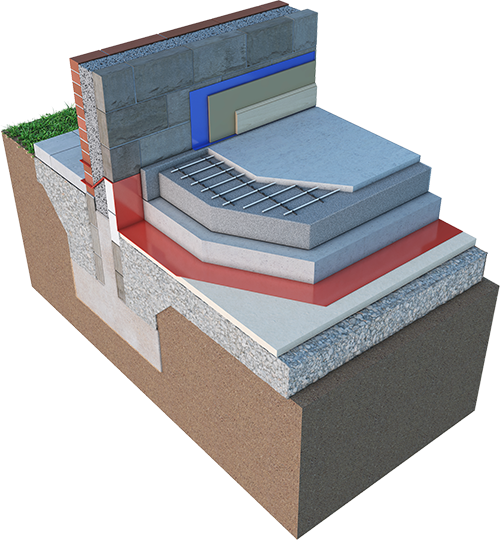

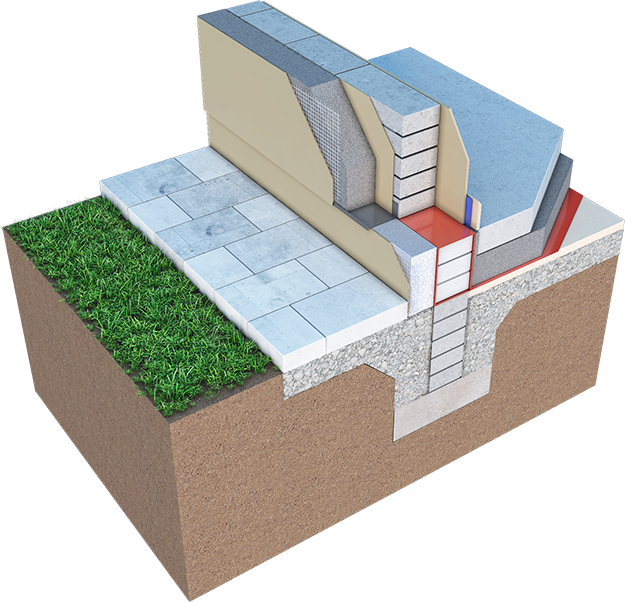

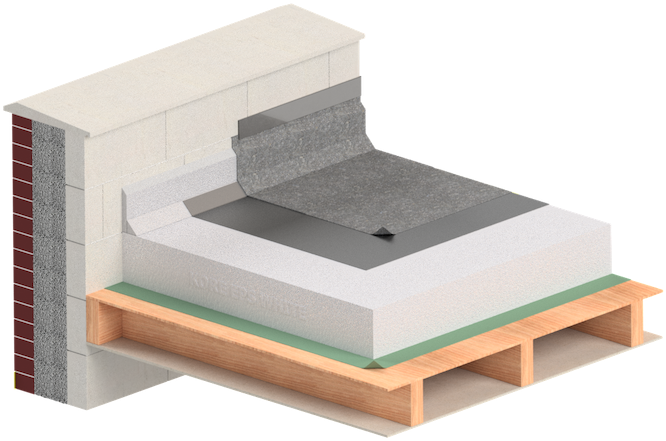

Low Carbon Floor Insulation Applications

Achieve Part L 2021 and nZEB with a lower carbon footprint. KORE’s Low Carbon EPS is available in White & Graphite-Enhanced Silver EPS70, 100 & 150 floor insulation.

Achieve the same low ground floor U-values in the foundation with low carbon EPS. Available for components of the foundation system up to EPS100 with the same NSAI Agrement Certification.

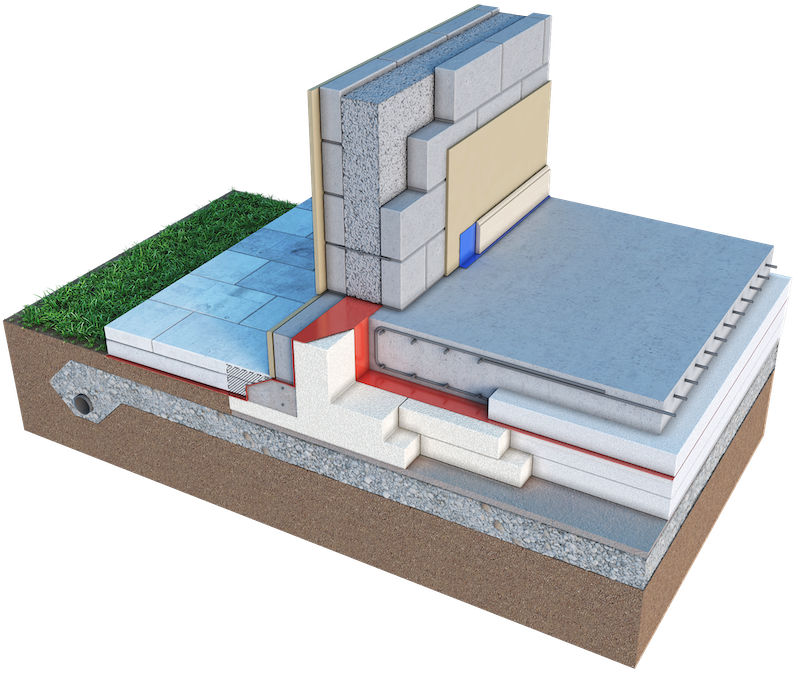

Low Carbon Wall Insulation Applications

Insulate cavity wall applications with low carbon KORE Fill Diamond. This lower thermal conductivity cavity wall insulation system can achieve Part L 2021 with 170mm KORE Fill Diamond in new build applications.

KORE’s Low Carbon EPS is available for KORE External wall insulation boards up to EPS150 White & Silver. Combined with a certified external wall render system you can easily achieve nZEB and Part L 2021 in new build and retrofit applications.

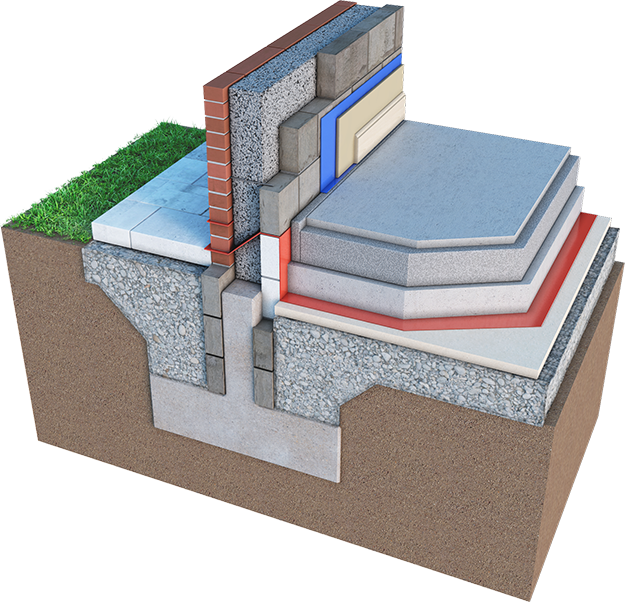

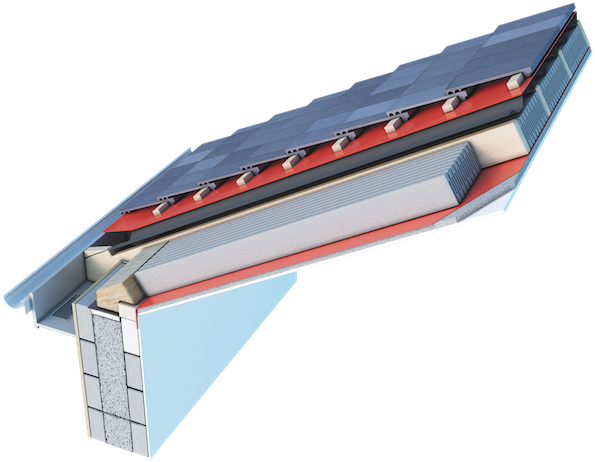

Low Carbon Roof Insulation Applications

KORE Low Carbon EPS is available for a range of flat roof applications, including cold & warm flat roofs, inverted, metal roof decks and tapered flat roofs.

KORE Lock Warm & Cold Pitched Roof Insulation is now available in low carbon EPS. Offering U-values that meet & exceed Part L 2021, cost-optimal and easy to work with and install.

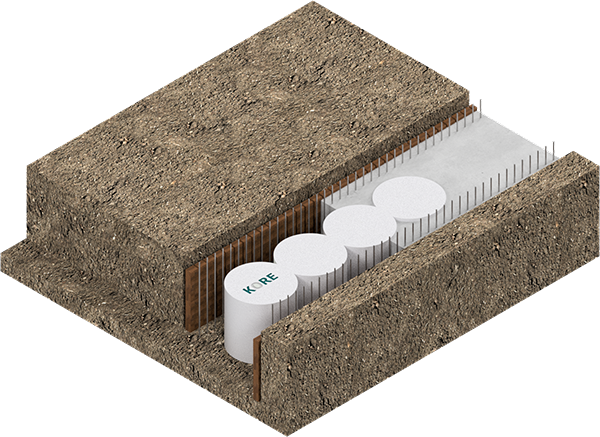

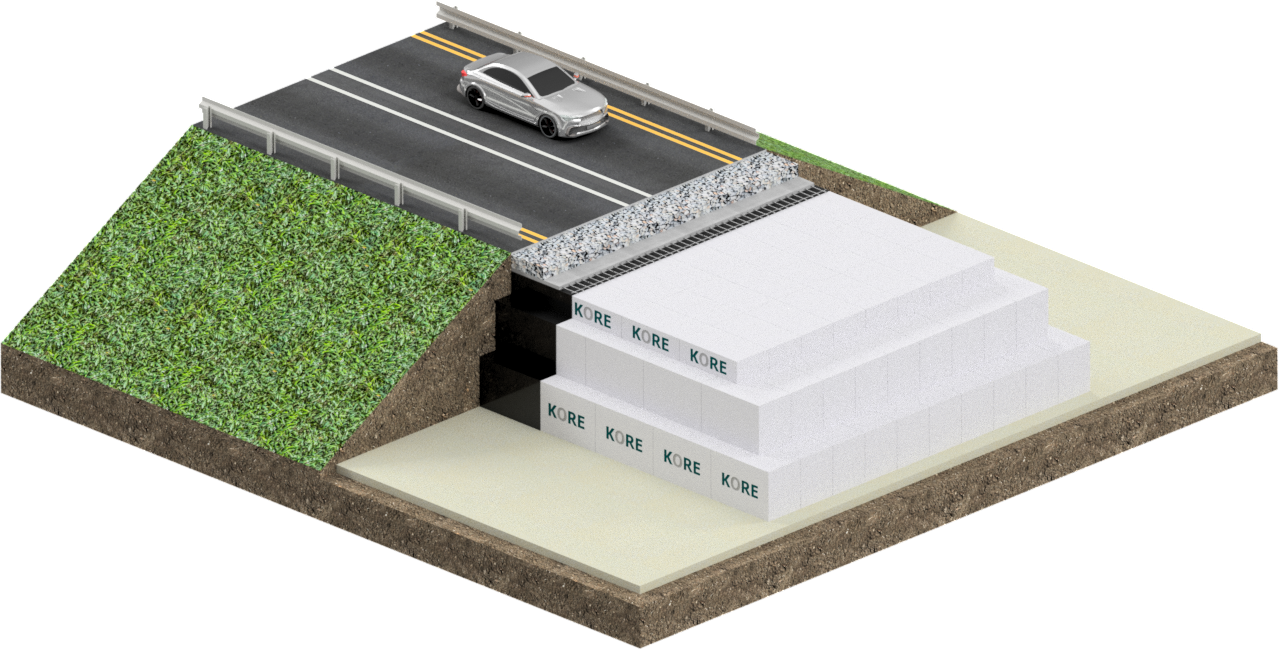

Low Carbon Civil Engineering Applications

KORE Low Carbon EPS can be utilised for a wide range of civil engineering applications, including for use as void formers and void fillers for reducing the weight of concrete.

KORE Geofoam made from low carbon EPS is the deal solution to replace traditional earth materials like soil, pebbles and concrete, as a soil substitute

REDcert2 Certification

KORE Low Carbon Insulation has received full REDcert2 Certification. This third-party verification ensures that sustainable material flow is fulfilled and maintained from the production of raw material to the manufacture of KORE Low Carbon Insulation Boards.

100% of the fossil-based raw materials required for the manufacturing of this product were replaced as biomass certified as sustainable.

NEXT GEN EPS INSULATION

What is KORE Low Carbon?

With the REDcert-certified biomass balance (BMB) approach, fossil resources needed to produce EPS raw materials can be replaced 100% by renewable raw materials. This production method saves valuable resources while reducing the CO2 impact. Since renewable and fossil raw materials are mixed in production and cannot be distinguished from each other, the renewable portion is allocated to Neopor® BMB using a mass balance approach. Both the allocation process and the product itself, have been certified by an independent auditor.

The biomass-balanced products Neopor® BMB protect the environment and climate without sacrificing the usual quality: This is because they are unchanged from their fossil counterparts in terms of formulation and properties.

The use of renewable raw materials reduces the carbon footprint of Neopor® BMB by 90% compared to traditionally produced Neopor®.

Watch the Neopor BMB video here.

KORE’s Low Carbon EPS offers the same benefits found in our traditional insulation materials, with no loss in thermal performance or thermal conductivity. KORE EPS remains moisture and water resistant, non-toxic and chemically inert, lightweight, versatile and cost-optimal when compared to competing insulation materials.