Did you know that uninsulated solid floors or suspended floors can contribute to ten percent of a home’s heat loss? Even worse, it can be considerably more expensive to insulate a floor after the fact, or even downright impossible without significant disruption to the home and its occupants. Floor insulation should not be thought of just as a way to meet building regulations, but as a product that contributes to a home’s comfort and the health and wellbeing of those that live there. In this post on the KORE blog we’ll break down the importance of floor insulation for your next new build, extension or even retrofit project.

What are Ireland’s Building Regulations for floor insulation?

Current Building Regulations in Ireland (Part L 2011) require a ground floor U-value of 0.21W/m2K in builds without an underfloor heating system. This is reduced further to 0.15W/m2K in ground floor constructions that incorporate an underfloor heating system. The proposed changes to Part L 2018 (as noted in the public consultation document) reduce the backstop U-value to 0.18W/m2K without an underfloor heating system. The regulations will stay the same at 0.15W/m2K in builds with underfloor heating.

For existing buildings, the minimum U-value for ground floor (Part L 2011) is 0.45W/m2K and 0.15W/m2K when used in conjunction with an underfloor heating system. These numbers do not change in the proposed changes to Ireland’s Building Regulations, however, when the upgrades to the building’s envelope exceed 25% of the total surface area, the building as a whole must be upgraded to a cost optimal level where technically, functionally and economically feasible. The cost optimal level is defined as 125 kWh/m2 /yr when calculated in DEAP.

Avoiding thermal bridging with floor insulation

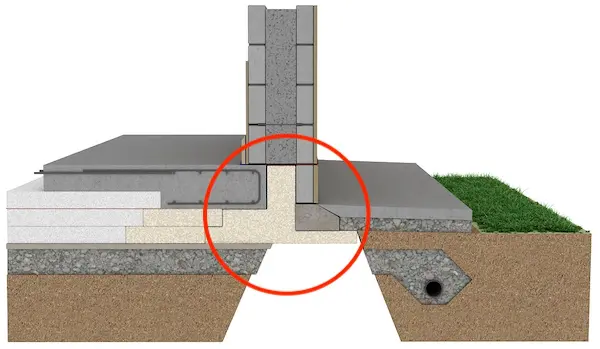

In addition to achieving optimal ground floor U-values, it’s also important to limit thermal bridges (cold bridges) especially at the wall to floor junction. There are several ways to limit thermal bridging when installing floor insulation. The use of vertical upstands (KORE Perimeter Strips) of insulation can be used to separate the screed or slab from the wall. Perimeter strips made from EPS insulation need to be level with the top of the screed or concrete slab and continue down and be level with the bottom of the floor insulation. The floor insulation and the perimeter strip should be closely butted and form a right angle, preventing heat loss where the screed or concrete meets the wall. KORE recommends using 35mm of EPS70 Silver (KORE Perimeter Strips) to prevent thermal bridging by ensuring continuity of the insulation. 35mm EPS70 Silver will achieve an R-value of 1.1 to comply with accredited construction details (ACDs).

KORE’s Insulated Foundation System can also be used to eliminate thermal bridging at the wall to floor junction. The insulated foundation incorporates both EPS floor insulation and structural grade EPS300 to fully insulate the foundation of the build. This system wraps the entire foundation in a continuous layer of EPS, removing the need to use KORE Perimeter Strips. KORE Insulated Foundation Systems are fully engineered for each individual project and can be designed to suit most ground conditions. The detail below shows a virtually thermal bridge free design combined with KORE Fill Cavity Wall Insulation, but can also be designed for timber frame, solid block walls, ICF and beyond.

Choosing the right type of floor insulation

Whether you’re an architect looking to specify floor insulation, or a self builder comparing products for a new build or extension, there is no shortage of materials to choose from. Choose a material with a proven track record, one that will last the lifetime of the building with minimal upkeep and provide excellent thermal performance with full technical back up from the manufacturer. For example, 150mm of KORE Floor EPS70 Silver with a 50mm screed can easily achieve a U-value of 0.15W/m2K (nZEB-ready) for a floor with a perimeter/area ratio of 0.4, typically at a generous cost savings when compared to other materials. For a full foundation approach, KORE’s Insulated Foundation System has achieved U-values as low as 0.09W/m2K, and can typically provide U-values around 0.10W/m2K – well exceeding current building regulations and nearly zero energy building (nZEB) requirements.

Some insulation materials are also prone to off-gassing, meaning its thermal performance may deteriorate somewhat over time. Expanded polystyrene floor insulation avoids this problem by insulating with 98% air. The thermal conductivity stated on the declaration of performance certificate is how the product will perform for the building’s entire lifetime, requiring no maintenance.

When choosing a floor insulation it’s important to consider the ground conditions. You should choose a material that is rot-proof, mould, water and moisture resistant. With the Irish and UK climate consider a material that can installed in damp ground conditions, such as EPS.

KORE’s EPS floor insulation, both White & Silver, have an Environmental Production Declaration certified by the Irish Green Building Council and EPD Ireland – a first for EPS insulation in Ireland. This makes achieving LEED, BREEAM and Home Performance Index certification easier. The manufacturing process is also CFC and HCFC free. KORE Floor Insulation is also chemically inert, so it can be handled safely on-site without the need for specialised equipment. As the number of recycling collection points continues to grow, EPS can also be recycled at the end of the building’s lifespan.

Building Information Modelling (BIM) object files for KORE Floor Insulation are also available, helping with planning, design, construction and facilities management throughout the lifecycle of the project.

A happy and healthier home

No matter the insulation material you choose, it’s essential the product is installed correctly, meeting or exceeding building regulations whenever possible. Partner with a company that can help you throughout the project, including U-value calculations, condensation risk analysis, thermal bridging analysis, temperature factor analysis, on-site visits for quality checks and complete technical back up.

Whether you’re installing floor insulation in your own home or on behalf of a client, choose a material that’s environmentally sustainable, high quality and cost effective. A properly insulated building means a healthier indoor environment, year-round comfort and a decrease in energy spend and associated carbon emissions.

See how much you can save by choosing KORE’s nZEB-ready EPS floor insulation for your next project.